As an introduction though, why not go to the Blog overview first.

art@spitfireart.com

01273 843749 07976 312058

A look at the central tunnel panels.

All of these panels can be carpeted, and I recommend www.automobiletrim.com and their TCN/10 lining carpet. Alternatively, they can covered in vinyl or leather.

The angled tunnel cover allows slightly more "hip-room". The RHD drivers side is slightly narrower than the passenger side, not by much, just 40mm, but every mm on the hips is ..well, a bit more room! For LHD cars, this isn't a problem. if you visit www.aerobarrelback.blogspot.com you'll see how one client did a superb job covering his tunnel in vinyl. Note the bare metal chassis, this is for the authorities in Holland to inspect all welding integrity, after which they grant a new chassis number, enabling registration. Most UK and US clients go for a powder coated finish once the chassis has been blast prepared.

The angled tunnel cover allows slightly more "hip-room". The RHD drivers side is slightly narrower than the passenger side, not by much, just 40mm, but every mm on the hips is ..well, a bit more room! For LHD cars, this isn't a problem. if you visit www.aerobarrelback.blogspot.com you'll see how one client did a superb job covering his tunnel in vinyl. Note the bare metal chassis, this is for the authorities in Holland to inspect all welding integrity, after which they grant a new chassis number, enabling registration. Most UK and US clients go for a powder coated finish once the chassis has been blast prepared.

As an amendment 7/2/21, I bought a Caterham Seven 160 model (Suzuki 660cc turbocharged engine) in December 2020 and this is the narrow S3 model, and is this cockpit tight or what! I've always said to clients, if you can fit in a Caterham, then you can fit in one of mine! if not, just lose weight, It'll do you some good!

A view looking forward from the rear on the Right hand side. Notice the rear tunnel cover angle, this remains on the RHS irrespective of RHD or LHD cars. Note the elongated slot through which the angled hand brake lever fits. The other exposed angled hole allows the main gear change lever to protrude.

Another view of the tunnel rear cover. Within the cut-out will lie the main rear bearing through which the rear propshaft passes down to the swing arm and final drive.

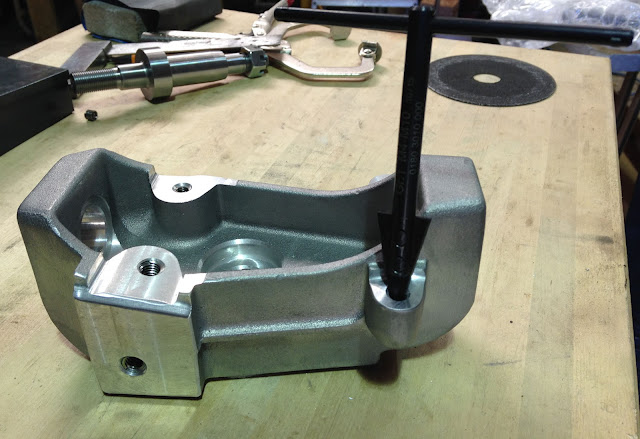

The angled tunnel panel has to transition through to a right angle, via the odd shaped piece shown above.

With the rear tunnel cover removed, the angled piece to which the hand brake lever bolts, can be seen.

Close-up of the hand brake lever location.

Close-up of the transition panel.

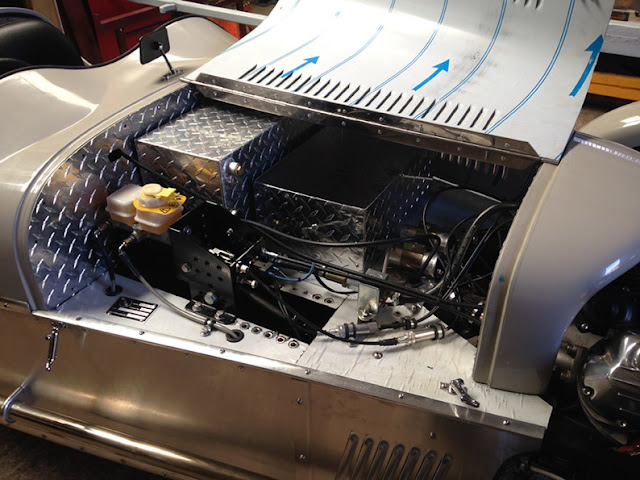

Just forward of the transition panel is the removable panel behind which, the reversing gearbox is situated, and it is bolted down to the angled plinth shown.

The forward RHS panel is also removable enabling access to fit/dismantle the front propshaft.

LHS forward panel which is riveted in place.

LHS removable panel, enables one to fill the reversing gearbox with oil, and to check oil level.

Intermediate rear LHS panel which is fully riveted in place.

Rear most small LHS panel is detachable and allows access for hand brake cable adjustment etc.

Final look at the LHS of the tunnel panels.